Autor/-in:

Kurtcuoglu Deron

It Just Won’t Stick!

The effect of different reagents on the non-stick property of seasoned cast iron pans

Sigrist Raphael

Kantonsschule Im Lee

Fach: Chemie

Abstract

Background

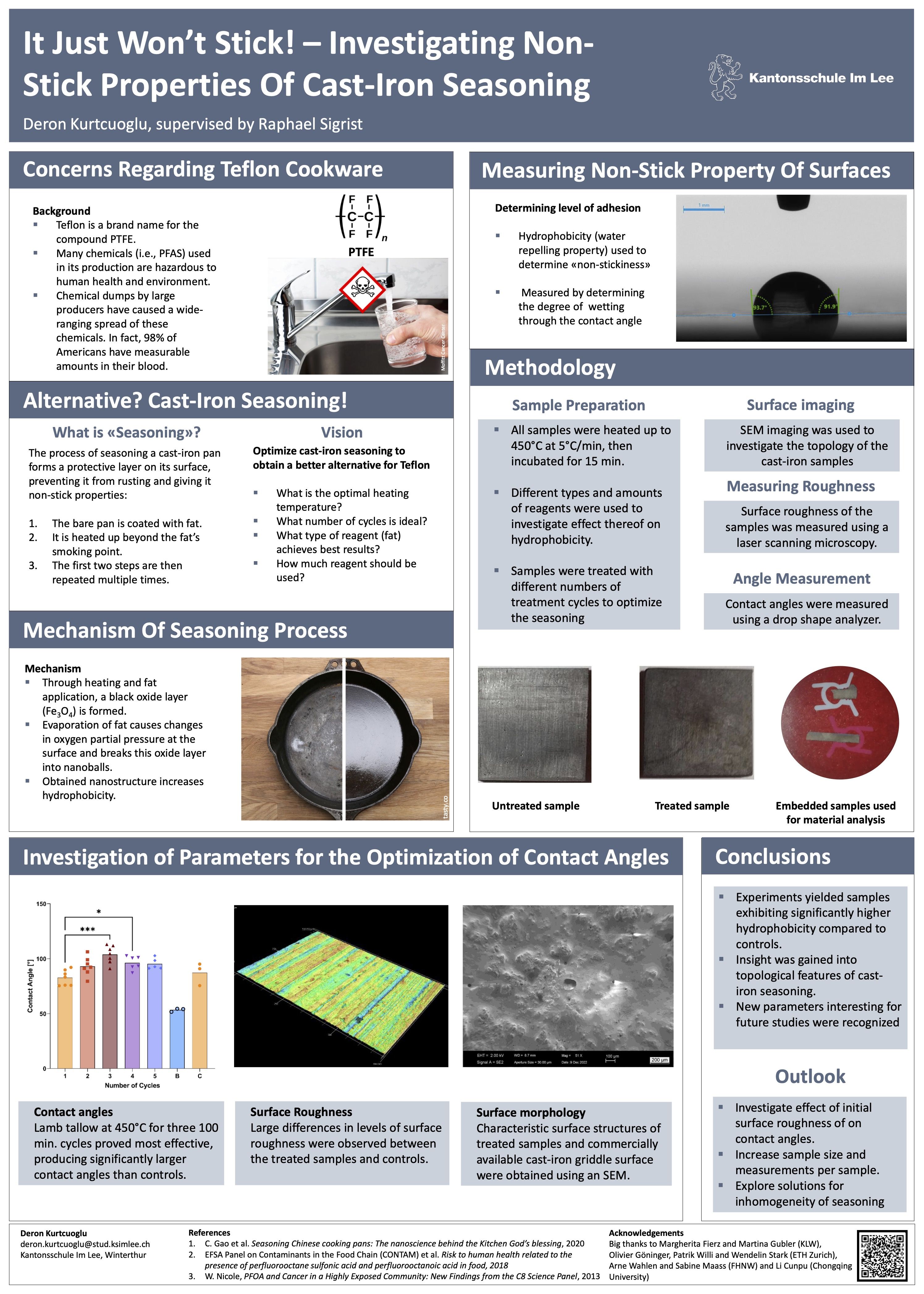

Per- and polyfluoroalkyl substances (PFAS), which are employed in the production of polytetra-fluoroethylene (PTFE, also known by its brand name Teflon) pose well-documented health and environmental hazards. Therefore, substitutes for PTFE need to be considered.

Objective

To explore alternatives to PTFE in conventional non-stick pans, an older, well-known material for cookware was investigated: cast-iron. The idea was to study the process of producing a non-stick coating (referred to as seasoning), thereby to better understand the steps required for improving cast-iron as an alternative to PTFE cookware.

Methods

Seasoning refers to the process of creating a coating on cookware by overheating a small amount of well-distributed fat or oil on the surface. Several reagents (tallows and fatty acids) were used to season cast-iron samples. The process was conducted with different amounts of reagent and with varying numbers of incubation cycles. Contact angle measurements of water drops on the samples were made to assess hydrophobicity.

Results and Conclusion

By conducting experiments that compared variations of the chosen parameters, cast-iron samples with contact angles larger than those of controls were produced, indicating an increase in hydrophobicity through the seasoning process. Moreover, surface roughness was found to be an important parameter to be optimised for improving non-stick properties. In conclusion, seasoned cast-iron cookware should be further studied as alternative to conventional PTFE products.